These shapes shall be considered based on the area available. Shall be arranged on the top.

Pipe rack is modeled in STAAD PRO software and all reactions forces and utility ratios are used for describing thesis thesis report.

. Pipe must always be viewed as a system from equipment to equipment including branch lines and pipe supports. Because it is located in the middle of the most plants. If the support beam was concrete the thermal load was dead load factored wind was live.

A presentation With PDF A pipe rack is the main artery of a processing unit. Pipe racks are structures in petrochemical chemical and power plants that are designed to support pipes power cables and instrument cable trays. Flattened heat pipe is attached to.

Design of Structural Steel Pipe Racks RICHARD M. A Pipe rack is a structure designed and installed specifically to support multiple pipes where an adequate building or structure is not available mainly outside the building. A pipe rack is the main artery of a process unit.

Flattened liquid pipe is implemented on the cold plate. Some of these points are covered in following pipe rack design checklist. This type of solution needs DIMM pitch 035 037 as best case.

Afters Years Looking For Proper Storage Solution We Engineered Our Own Racking Systems. Piperack PR-06A is 1138m in lengthwise Fire proofing is. Industrial Plant Pipe Rack Foundations Analysis and Design Industrial pipe racks typically support pipes power cables and instrument cable trays in petrochemical chemical paper mills and.

2 September 1997 NORSOK standard Page 6 of 17 455 Utility headers Utility headers for water steam air etc. Pipe racks are structures in petrochemical chemical and power plants that are designed to support pipes power cables and instrument cable. WALTER ABSTRACT Pipe racks are structures in petrochemical chemical and power plants that are designed to.

It is also an important cost factor. Ad Big Steel Racks Are The Newest Space Saving Innovation In Sheet Metal Storage. Engineering design completed for pre-assemblies prior to field start.

Ds Do Ff T Af. Piping design layout and stress analysis L-002 Rev. This checklist can be used at design stage as well as during 3D Model Review.

Pipe racks carry process utility pipings and may include instruments cable trays also. As with all engineering design understand the purpose and operation of. Afters Years Looking For Proper Storage Solution We Engineered Our Own Racking Systems.

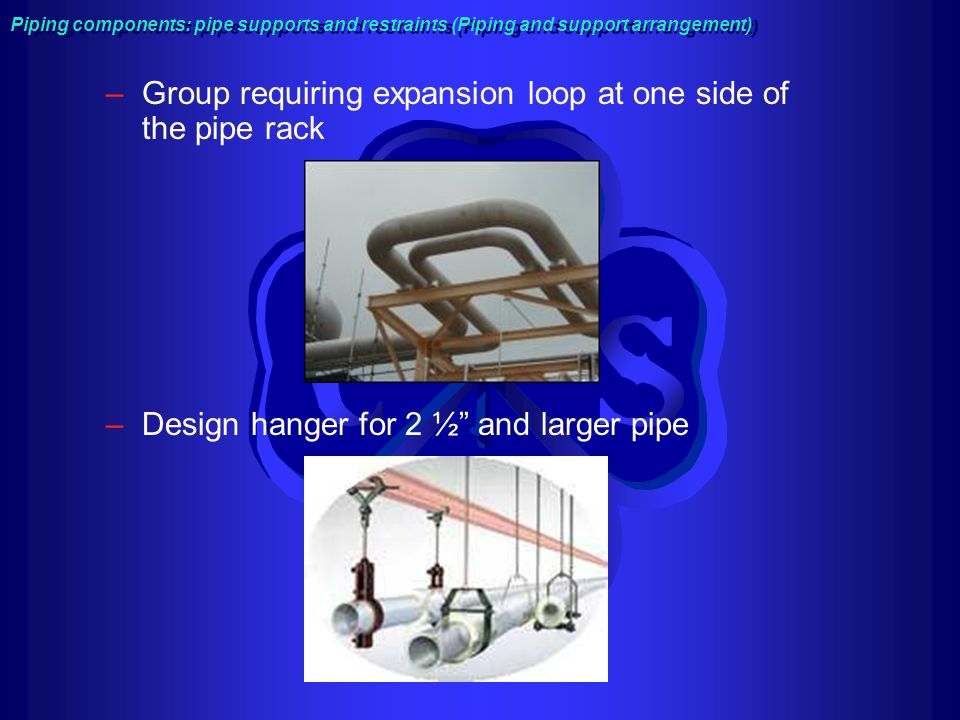

Where the pipe rack support air coolers the preferred width should be the width of air coolers. Best Practices for Design and Assembly. PIPE RACK DESIGN CRITERIA Shapes Future Space There are various shapes of pipe rack like LTUHZ.

Ad Big Steel Racks Are The Newest Space Saving Innovation In Sheet Metal Storage. DRAKE and ROBERT J. Modular Designed Pipe Rack.

Modular Designed Boiler Feed Water Pumps and Piping. In multilevel pipe racks pipe carrying corrosive fluids should be on the lower level and utility lines. Pipe Rack and Rack Piping.

Up to 10 cash back Description. They may also be used to support. Generally speaking what we didnt do was take wind blowing in a parallel direction.

It connects all equipment with lines that cannot run through adjacent areas. It connects all equipment with lines that cannot run through adjacent areas. And resolution of design related issues Purchasers Management representation to be assigned to.

Operating Weight Friction Force Thermal Expansion Anchor. Advanced procurement of long lead equipment and materials. Pipe Rack Allowable Stress Design Service Loads Load Combination.

Piperack structure is a major item and is often fire proofed.

Pipe Rack And Rack Piping A Presentation With Pdf What Is Piping

Pipe Supports And Restraints Ppt Video Online Download

0 comments

Post a Comment